In the fast-paced world of medical device innovation and engineered products, success hinges not just on what you make, but how you make it. At UFP MedTech prototyping before scaling to manufacturing isn’t a luxury; it’s foundational to delivering high-performing products with predictable quality, faster time to market, and long-term reliability.

What Is a Development Lab and Why It Matters

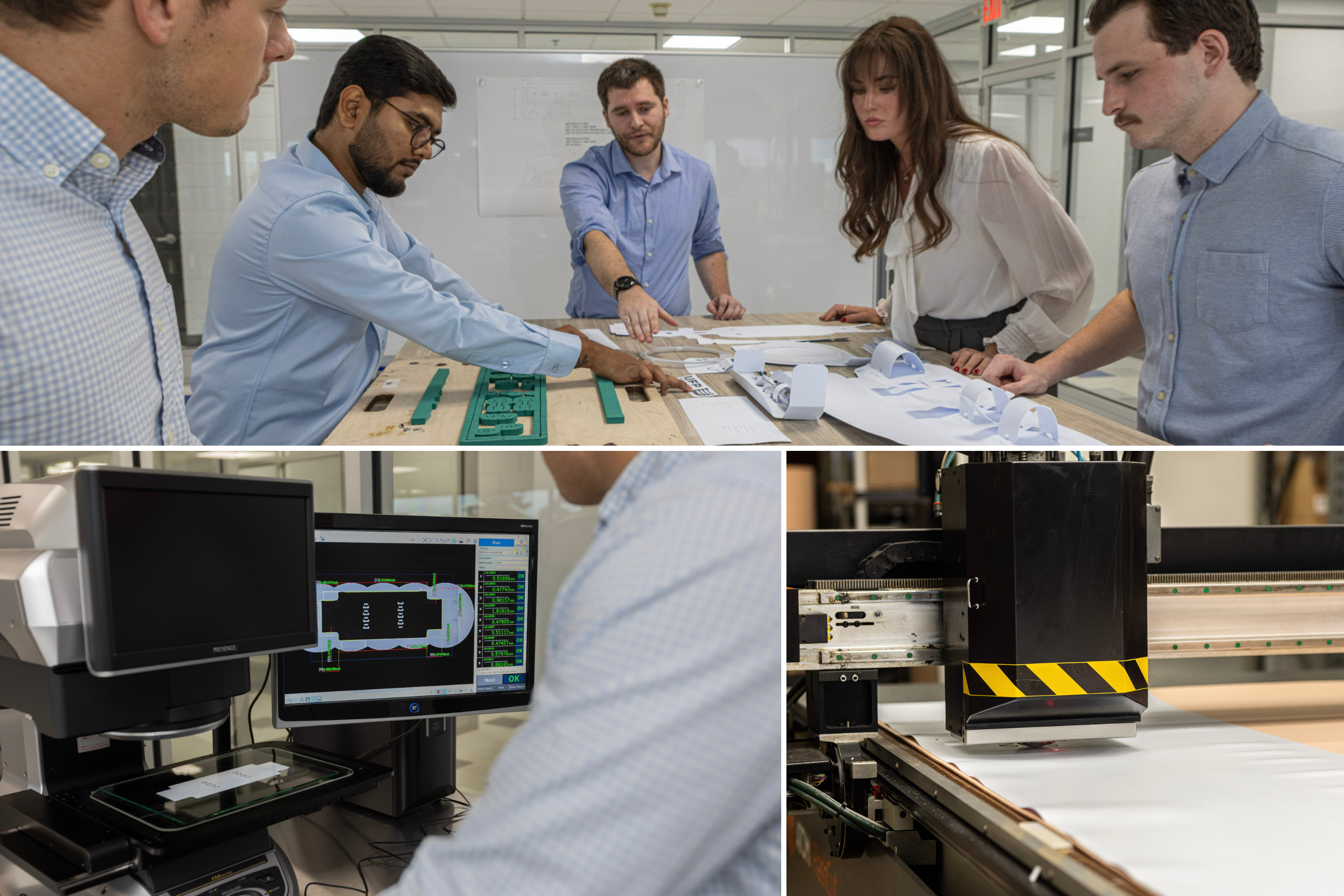

A Development Lab is a dedicated environment where ideas transition from concept to reality through structured prototyping, testing, and validation. It combines specialized tools such as rapid prototyping technologies (including 3D printers, thermoplastic welding, and CNC equipment), materials testing systems, and in-house tooling facilities with experienced engineers. At UFP, these labs enable rapid design iteration and informed material selection, engineering validation, and early-stage risk mitigation well before production lines are engaged. This front-end rigor helps ensure smoother transitions from development to full-scale manufacturing.

Key capabilities that define a successful development lab include:

- Rapid Prototyping and Tooling: Producing functional prototypes quickly (often within 24–72 hours) to evaluate form, fit, and function in real time

- Design for Manufacturability (DFM): Applying engineering expertise to ensure that what works in prototype will succeed in full-scale production

- Material Expertise and Selection: Leveraging deep understanding of medical-grade foams, films, plastics, and composites to match specific performance requirements

- Pre-Production Validation: Testing early prototypes under conditions that mirror production conditions, minimizing downstream surprises

These capabilities create a controlled, feedback-rich setting where engineering hypotheses are validated or refined before committing capital to tooling, purchasing, and high-volume operations.

A Competitive Advantage for UFP and Our Customers

Not all contract development and manufacturing organizations (CDMOs) invest in robust, multidisciplinary development labs. UFP Technologies does so intentionally. For our customers, these labs are more than workshop spaces; they are value-creation centers that protect timelines, control cost, and accelerate commercialization.

Our Development Labs are staffed by cross-functional teams of engineers, material scientists, technicians, machinists, and quality specialists who work together to move ideas efficiently from concept to production. Materials and process engineers guide material selection, mechanical and design engineers translate requirements into manufacturable solutions, technicians and machinists build and refine prototypes and tooling, and quality and regulatory experts ensure designs meet applicable standards and are ready for scale. This collaborative model allows UFP to operate not simply as a manufacturer, but as a true innovation partner and an extension of a customer’s R&D, engineering, and production teams.

How clients benefit:

- Faster Time to Market: Early prototyping and validation identify challenges sooner, reducing redesign cycles after production launch

- Risk Reduction: Material choices, manufacturability assessments, and prototype testing uncover latent issues before they become costly production problems

- Optimized Manufacturing: Prototypes designed with manufacturing constraints in mind ensure smoother, more predictable scale-ups

- Cost Efficiency: Eliminating late-stage surprises avoids waste in tooling, materials, and production run errors

This proactive approach is especially critical in medical devices and sterile packaging, where subject matter expertise and process precision directly impact product safety and regulatory compliance.

Conclusion

For UFP MedTech, development labs are foundational assets. They are where ideas are stress-tested, where manufacturability is assured, and where risk is managed long before production begins. This investment in early-stage innovation delivers measurable advantages: faster product launches, fewer surprises, improved cost control, and stronger alignment between design intent and actual performance. In today’s competitive and highly-regulated medical device landscape, this isn’t an optional step; it’s an essential differentiator rooted in expertise, collaboration, and deep engineering rigor.