Compression Molding

Thermoplastic Welding

High-Speed Die Cutting

Vacuum Forming

Thin Film Thermoforming

Injection Molding

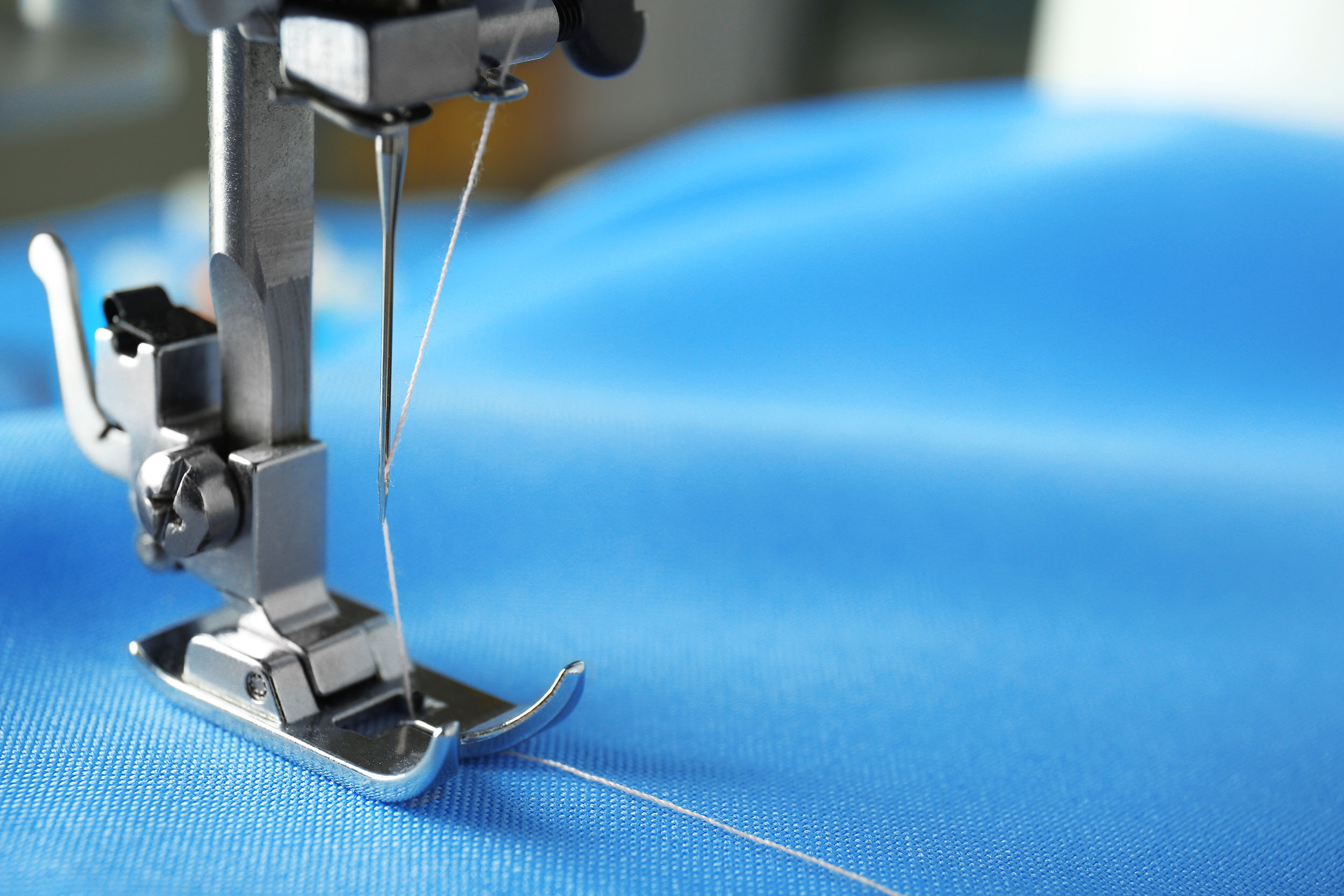

Cut and Sew

Fluid & Air Management

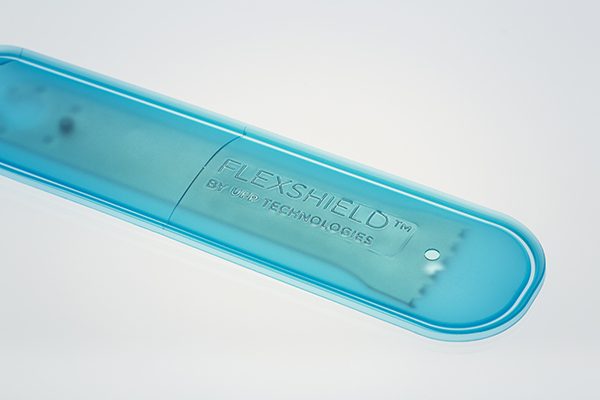

Tube Finishing

Lamination

Printing & Decorating

Packaging

Cleanroom Manufacturing

Complete Device Assembly

Request a Consultation