Rooted in flexible materials and medical device manufacturing expertise, our reach has grown to include every capability: design talent, skilled engineering, materials selection, rigorous prototype testing, manufacturing, quality management systems, and supply chain management. Wherever you are in the evolution of your product, we have the ingenuity and acumen to execute it and expedite it.

Our Expertise

- Extension of customer R&D and engineering teams

- Start Ups to OEMs

- Lean 3P (Production Preparation Process) development

- Pre-commercial, rapid prototyping, and material specification

- Speed to market, cost, and outcome focused

- System integration

- Quality management systems

- Contract manufacturing

To request a consultation, contact us below or give us a call at 800-372-3172

Our Focus

Infection Control

Protective Packaging

Surfaces & Support

Interventional & Surgical

Therapeutics

Wearables

Wound Care

Diagnostics

Fast Prototyping

We understand the importance of delivering prototypes quickly and getting your product to market faster.

- Multiple prototype lab locations

- Design for Manufacturability (DFM)

- In-house tooling: 3D printing and machining

- CNC cutting: laser, water jet, and knife cutting

- Printing: silk screen, hot stamp, and laser ink jet

- Dedicated engineers, technicians, and machinists

Our Medical Device Development Process

Resources

Medical Foams

Thermoplastic Welding

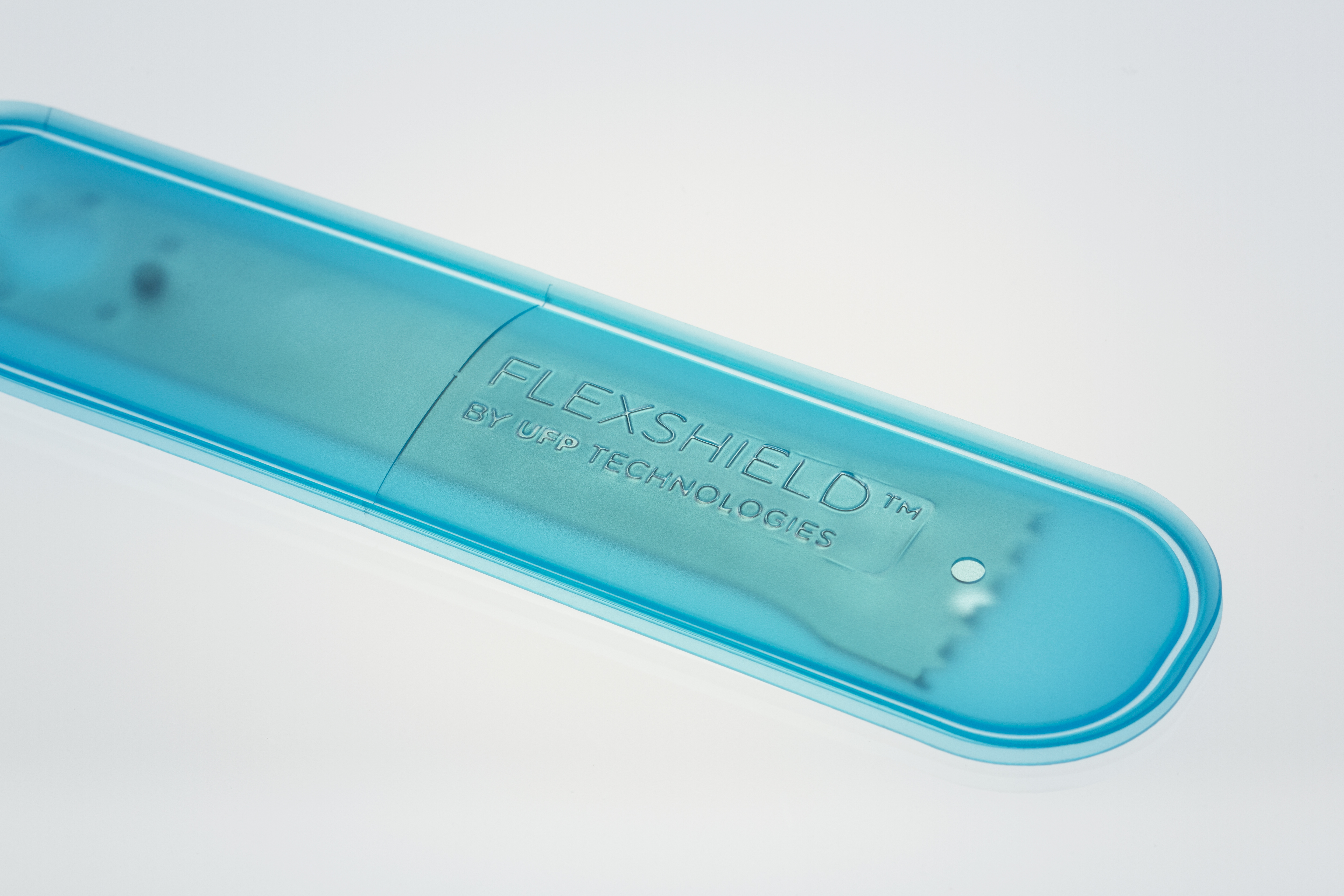

FlexShield