Capabilities

Medical High-Speed Die Cutting

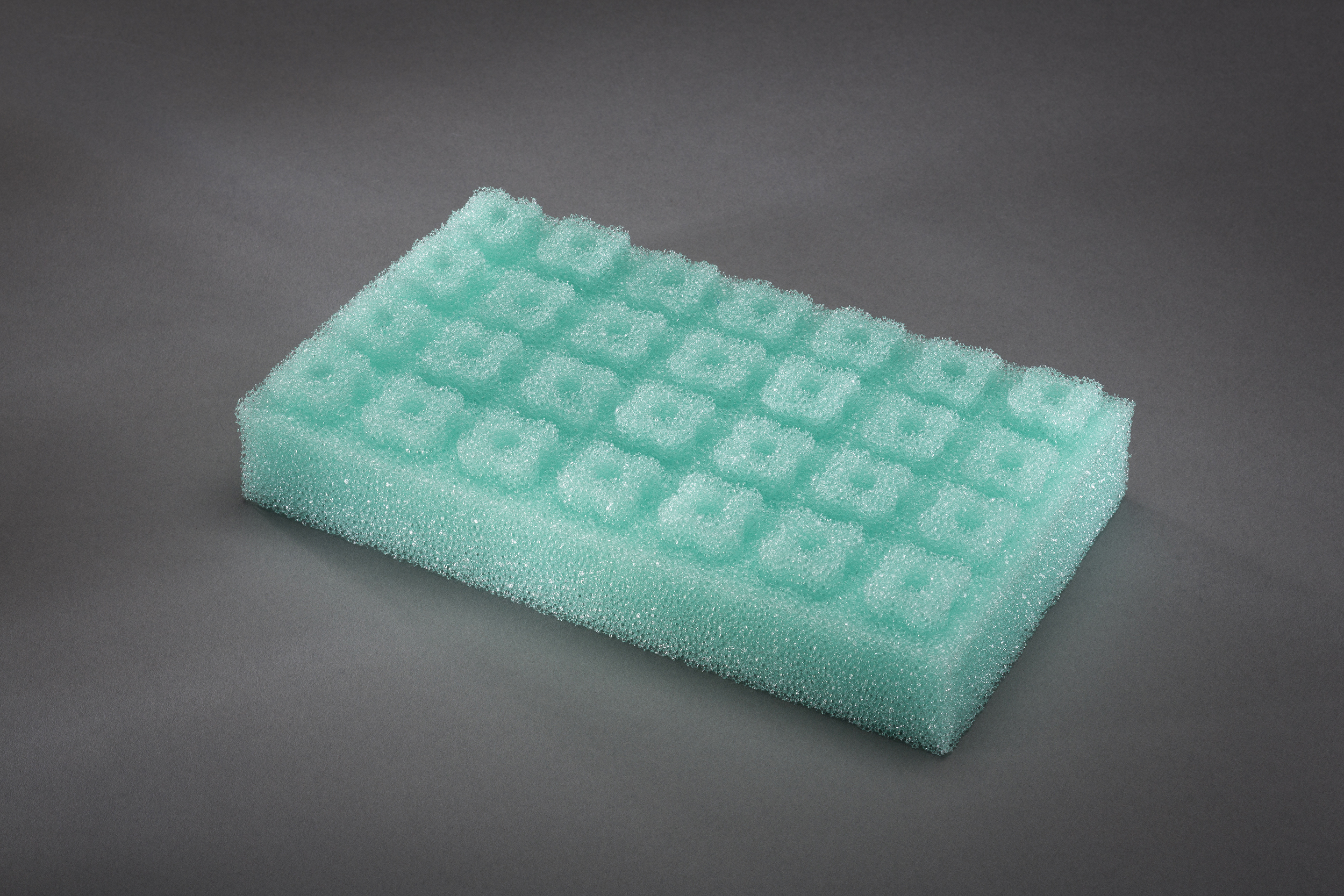

High-speed die cutting involves feeding a material into a press where it is cut into shapes of a predetermined size. Since sophisticated parts with a high level of quality control can be produced, this process is highly suited for medical components utilizing a range of foams and films.

Applications

- Infection Control Applicators

- Wound Care

- Protective Packaging

- Filters

- Wicking

Die cutting is the stamping out of parts and custom shapes using various types of tooling and high tonnage presses to ensure dimensional accuracy. UFP MedTech has extensive die cutting capabilities including high speed, optically registered, kiss cutting, rotary and vacuum systems across many of our manufacturing facilities. By combining the speed of die cutting with an accurate digital cutting system, UFP MedTech can create a wide range of precise high-volume medical components.

To request a consultation, contact us below or give us a call at 866-921-4718

* denotes mandatory fields.