The packaging system is a crucial component to getting a medical device to market on time. Time constraints with new projects can affect the entire packaging system design. The earlier a manufacturer starts thinking about the packaging of the medical device or system, the better things will turn out in the long run.

Most device manufacturers have a certified packaging engineer on staff or on retainer to assist during the design of a new device. Ideally, this person can inform the medical device manufacturer on any limitations and help mitigate any unrealistic expectations about packaging that could potentially hold up the launch date of a new device.

Since this role and step is so important to the process, device manufacturers without their own packaging engineers would benefit from consulting a medical device packaging specialist who will be able to alert them to protocols that may be crucial to gaining FDA approval down the line. Overlooking these considerations could affect a product’s expected launch date and result in lost revenue

Accelerated Aging Tests

As part of the quality control process, companies should conduct a series of accelerated aging tests, to determine how long the packaging system will last on the shelf. These tests can be a major factor in meeting timelines, schedules, and product launch dates. In some cases, it is important to have all the tests done concurrently to assess the materials to be used. The complete packaging system must be analyzed, including materials or components such as foam, blisters, trays, and/or lids for sealing. For quality assurance, the test should mimic the temperature and seasonal changes that will occur during the life cycle of these devices.

This series of accelerated aging tests can take many months, and the FDA will not approve a device before it is completed. Companies must submit their test results to the FDA and confirm that the packaging will support their shelf-life claim.

Packaging Materials

Time is also a crucial factor in selecting a manufacturing process and material. Shorter lead times may prohibit what materials and fabrication methods can be used for the packaging systems.

Medical device manufacturers are sometimes forced to use a process or material based on their lead times. For example, compression molding a packaging solution may not work due to the time to create custom tooling, and a die-cut part may have to be used. Selecting materials up front could help reduce overall lead time.

The following is a brief overview of some types of materials commonly used in medical device packaging applications:

TPU:

Thermoplastic polyurethane is a class of materials used for medical device packaging and components due to its excellent abrasion and puncture resistance. Most TPU resins meet USP Class VI standards. Packaging applications include: screws and rods, orthopedic implants, and surgical instruments.

PETG:

PETG is a tough, thermoplastic material that is easy to form. It is ideal for medical applications because it withstands radiation and chemical sterilization techniques without changing color. Applications include: orthopedic implant packaging, surgical instruments, and medical electronics.

Cross-Linked Polyethylene:

Cross-linked polyethylene foam is a closed-cell foam characterized by a compact feel and resistance to water that enables the material to be compression molded or thermoformed. It has many of the same properties as polyethylene foam but also has the ability to protect class “A” surfaces and is used extensively for packaging medical products and equipment. Applications include: case inserts protecting endoscopes and fragile medical devices, orthopedic implant packaging (such as hip, knee, and spine replacements), and surgical instruments.

HDPE:

High density polyethylene is a thin, light weight, USP Class VI resin material that is commonly used for backer cards (mounting cards) which can securely hold a wide range of medical devices and instruments. HDPE ships and stores flat, is 100% recyclable, is flexible and crack resistant, and can be die cut to incorporate a wide range of securement options. Backer cards are an excellent alternative to thermoformed trays.

Combination of Foams & Plastics:

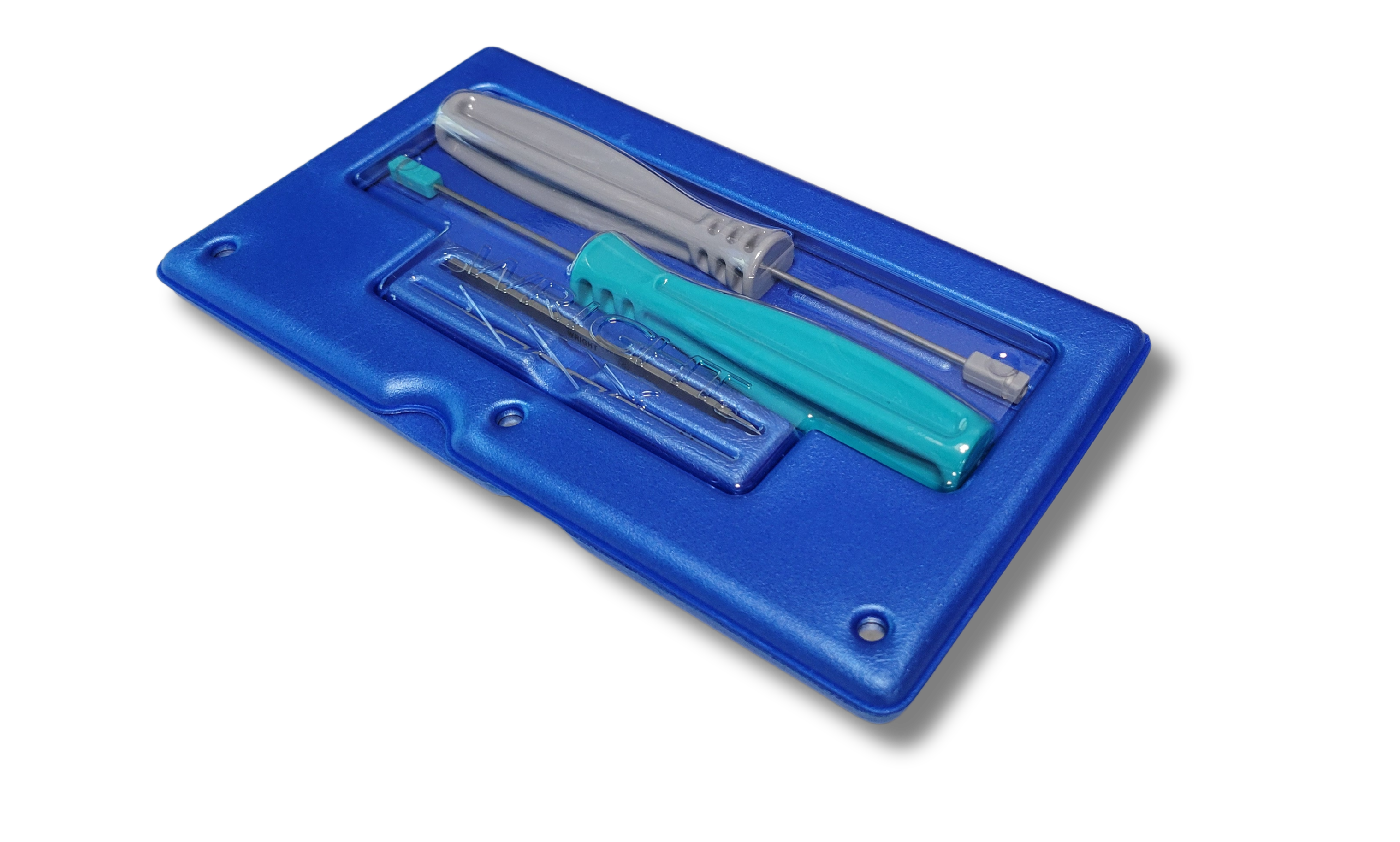

A packaging partner has the ability to fabricate almost any foam or plastic material. The combination of foams, films, and rigid plastics allows for the transformation of simple thermoformed trays and packages into highly protective cushioned packaging — providing a unique solution for shock and vibration protection throughout the distribution chain, while permitting sterilization for medical devices.

An example of a packaging system that incorporates a combination of materials is a surgical procedure kit for operating rooms. This package uses a compression molded foam clamshell, a thermoformed plastic window, a living-hinge, and a magnetic closure system. The kit, designed to be an all-in-one, disposable solution, provides nurses and doctors with all of their necessary tools in one portable and sterile package.

Conclusion

Working with a medical device packaging specialist could shorten the time it takes to get a device to market. Packaging design can be done concurrently with the rest of the product’s development. If a sample of the device is complete, the company can get started on packaging design as well. For the best results, start early and program packaging design and production into the release schedule of the device.