Capabilties

Lamination

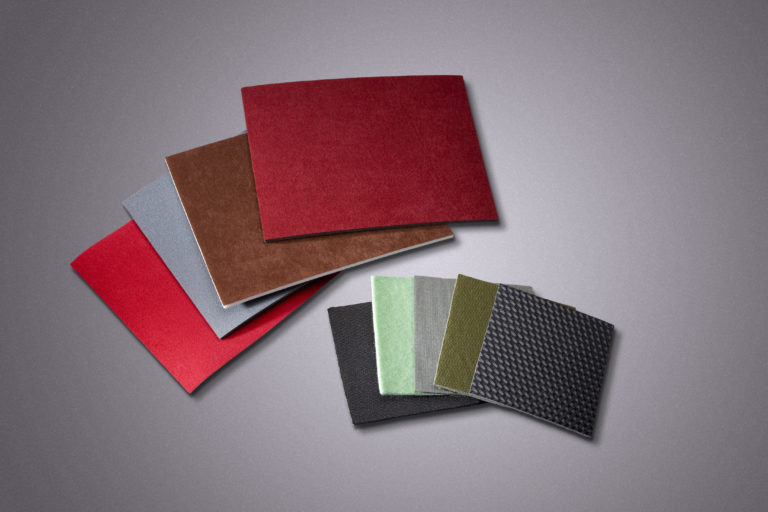

Lamination is most often used when there is a need to create a composite material, which is the combination of multiple materials such as foam-to-fabric, foam-to-film, or foam-to-foam. Our expertise at creating highly functional composites from hard to join materials ensures the optimal product for each application.

UFP MedTech has extensive experience in manufacturing custom medical solutions via lamination. Laminating is most often used as a fabrication method when there is a need to create a composite material, which is the combination of multiple materials (such as foam-to-fabric and foam-to-foam). Our lamination capabilities coupled with our access to a vast array of foams, fabrics and other specialty materials provide our customers a go-to solutions provider who can solve their unique medical device, component, and packaging challenges. We offer diverse lamination capabilities including flame/heat and adhesive.

Flame/Heat Laminating

Flame lamination is utilized primarily when combining a foam to another material. The heat melts the surface of the foam, turning it into a tacky substance that essentially acts as an adhesive. That surface is then combined with another material, such as a fabric, and the two goods are then bonded together under pressure.

Adhesive Laminating

Laminating with adhesives is one of the more traditional ways to make composite materials, and it remains an efficient and economical alternative for many applications. We have the ability to laminate a number of diverse adhesives such as heat activated, pressure sensitive, moisture activated and acrylic.

Request a Consultation