Our unparalleled expertise with protective materials ensures we will create the precise solution to meet your exact requirements.

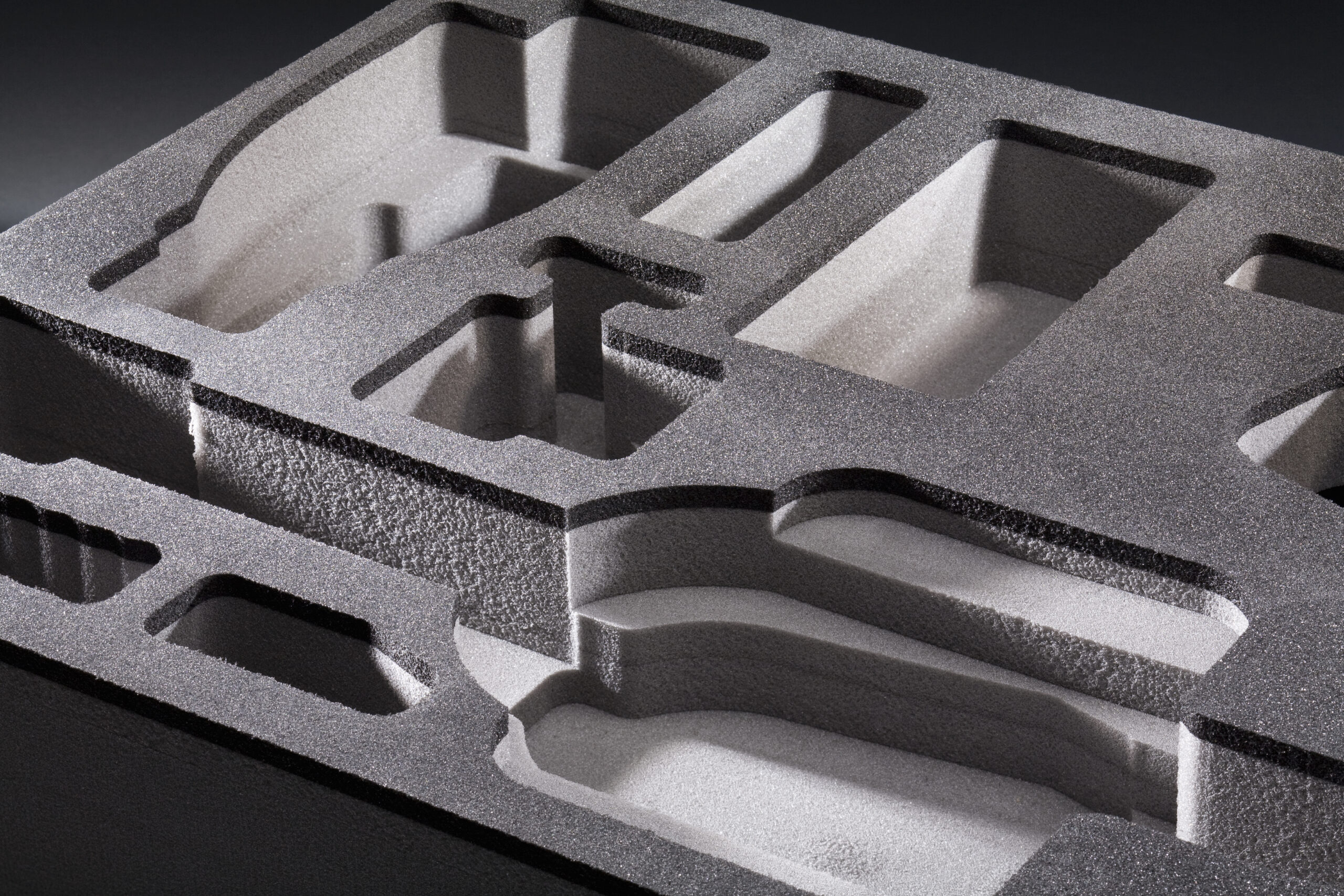

For decades, UFP MedTech’s robust, yet lightweight protective case solutions have ensured life saving devices and fragile products arrive undamaged and ready to perform when needed.

Applications:

- Return/Reuse for Repair and Refurbishment

- Orthopedic Implants

- Medical Devices and Equipment

- Surgical Instruments

- Samples and Presentation Kits

- Injectables

Choosing a Case and Insert

Whether you need to protect valuable medical equipment for shipping and storage or require a more secure way for salespeople to transport samples and demonstration units, UFP MedTech can create the perfect medical case for your application.

We can guide you through the entire process of developing a custom solution which includes selecting the necessary protective case and choosing the optimal foam.

Protective Case Selection

UFP MedTech can provide you with the best cases from the top manufacturers of plastic cases, soft-sided cases, ATA cases, aluminum cases, wood cases and metal cases. Depending on your application we will recommend the best protective case solution.

Foam Selection

Choosing the right foam is crucial for many medical applications because of safety regulations. Crosslinked foam is one of the most commonly used and can protect class “A” surfaces while offering antibacterial properties. Our crosslinked foam expanded with nitrogen provides a non-toxic, hypoallergenic, latex-free solution that can come in direct contact with skin and be used in operating rooms.

The ideal foam for your case insert will be suggested based on a variety of factors such as: weight, fragility and resistance to certain environmental elements.

XLPE is typically regarded as the highest quality packaging foam. It can be used to create long-lasting and extremely durable inserts that are the most aesthetically pleasing of all foam families. XLPE foam has many of the same benefits as polyethylene foam but also has the ability to protect class “A” surfaces. Its closed cell structure means that contaminants in liquids or the air cannot become trapped.For high purity applications, UFP MedTech offers XLPE that is expanded with nitrogen instead of chemical blowing agents, making it non-toxic, hypoallergenic, odorless, and excellent for skin contact.

Polyethylene foam provides great protection and durability for the interior of your case. It is a durable, lightweight material that is non-abrasive, non-dusting, and easy to fabricate. It exhibits excellent shock absorption and is impervious to mildew, mold, rot and bacteria. These qualities along with its excellent vibration damping, insulative properties and high resistance to chemicals and moisture make it ideal for packaging heavier items and for material handling applications.

Polyurethane foam provides excellent protection for light-weight, delicate objects with high fragility and/or lower drop height maximum. This open-cell foam provides excellent cushioning at a very reasonable cost and can be easily molded or cut to fit one’s particular application. It is used regularly in medical packaging where abrasion resistance is required and comes in a range of densities and colors.

Capabilities

As the leading manufacturer of custom foam case inserts in North America, UFP MedTech has the equipment and expertise to fabricate foam inserts to meet just about any application and budget.

Depending on the type of foam specified, quantity of inserts required, and complexity of the design, we utilize the following processes.

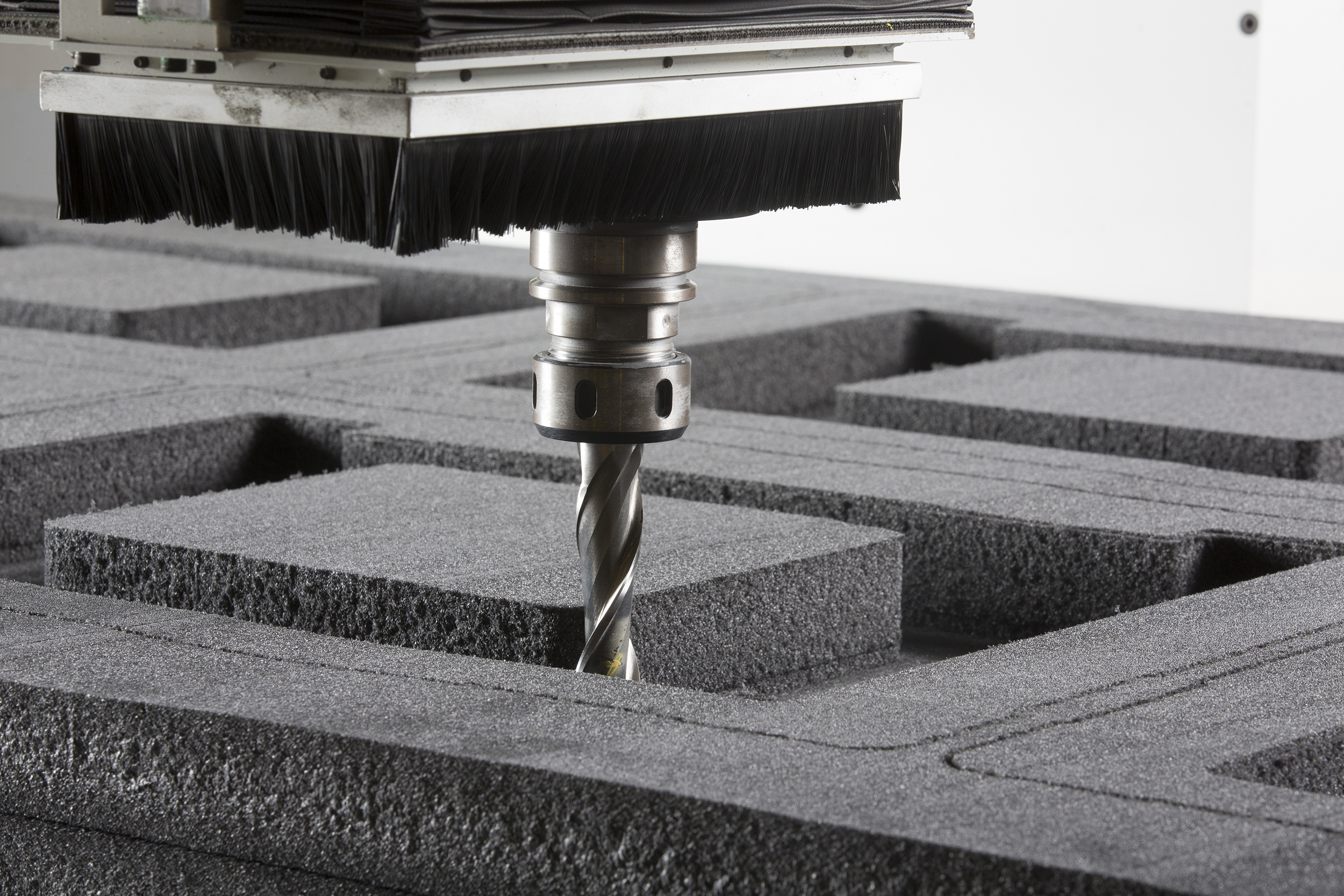

Routing

Used for manufacturing more complex inserts, our engineers utilize the latest technology to create patterns that will be routed using CNC machines.

Waterjet Cutting

This process, ideal for single and small volume inserts, requires no tooling and allows us to create sophisticated inserts in a wide variety of materials.

Die Cutting

Often used for inserts that are going to be purchased in higher volumes, this process utilizes a metal die that stamps foam sheets in to the exact specifications of the items to be packaged.

Product Identification System

UFP MedTech offers laser etching, laser cutting and plastic etching to enhance your case insert. We can etch part numbers onto plastic inserts placed into the foam or we can etch onto the foam itself. Etching onto your case insert is excellent for asset management, tool accountability, reducing foreign object damage and classifying sections of your case.

Request a Consultation