Of all the steps taken on the path from ideation and design to production and launch, medical device process validation is perhaps the most critical to ensure that when your medical device hits the market it is safe for use, reliable, and effective at improving patient care.

Process validation for medical devices is more than just a “check-the-box” list to complete for regulatory compliance. It’s a comprehensive process that paints a clear picture of the quality criteria to be implemented, maintained, and verified throughout your product’s lifecycle.

When validating a medical device, it’s important that you and your manufacturing partner collaborate closely, implement the most efficient tools, systems, and protocols—and agree on a process that puts the patient first. Here are five key considerations:

1. Ensuring proper design verifications and preproduction validations support the product’s intended use

Before production validation begins the medical device would have been cleared for use by the U.S. Food & Drug Administration (FDA). This means there are clear, unambiguous indications and contraindications for use approved by the FDA.

- Intended use: The general purpose of the device or its function, including indications for use

- Indications for use: The disease or condition the device will diagnose, treat, prevent, cure, or mitigate, including a description of the patient population for which the device is intended¹

2. Establishing design verification and validation

While “verification” and “validation” sound similar—and are key steps along the lifecycle of your medical device—they impact the manufacturing process in different ways. Per FDA mandates you must establish, by objective evidence, that your medical device meets both user needs and intended use via:

- Design verification: An examination confirming that your device meets established design specifications and product requirements at each development step

- Design validation: A process objectively proving the device meets user needs and intended uses by working as it should in the real world¹

In other words, you need to verify that your medical device is designed correctly and also validate that the medical device you produced matches that design.

3. Developing your production validation plan

Medical device production validation is the final phase of the product validation process and is conducted prior to mass production. It validates the R&D engineers’ selection of processes, materials, and tolerances.

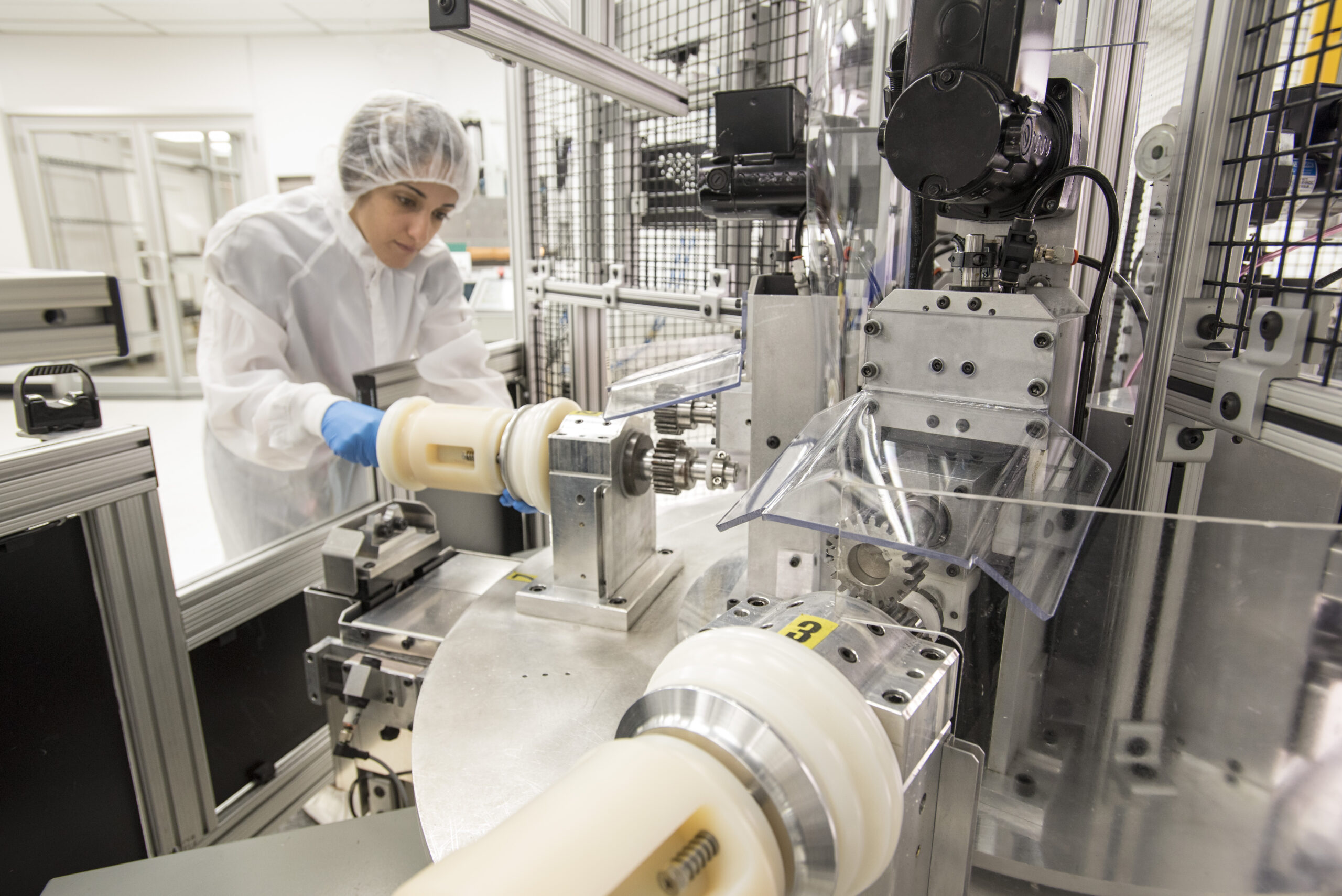

It is now up to the production team to verify that the equipment is properly and safely installed, as well as to identify the limits of acceptable quality to a predefined capability. It is imperative that testing occurs during the normal production environment to confirm the quality and safety of the product, thus ensuring the device meets patient needs and its intended use.

4. Conducting process validation for your medical device

This is where collaboration with your manufacturing partner is paramount and where everyone from scientists to engineers to clinicians must communicate. Your team must leverage the same set of tools and systems so your product’s manufacturing process remains reliable while prioritizing the patient at every stage. Process validation must:

- Establish equipment capability to operate within parameters

- Demonstrate equipment and instrumentation capabilities to operate within parameters

- Perform replicate cycles or runs to represent required operational range of equipment

- Monitor validated process during routine operation

- Requalify and recertify equipment as needed²

5. Maintaining a validated state through change control

Completing process validation is, of course, a crucial step for your medical device. Yet companies often lose the validated stage shortly thereafter because the product release criteria and data aren’t comprehensive to the validation—which makes it impossible for manufacturers to prove that the validated state has been preserved during production.

Effective change control is essential to maintaining a validated state. Any changes made during manufacturing and production must be noted into the device master record—a comprehensive history of each process and input that impacted the device, including:

- Device components and materials

- Work processes and constructions

- Environmental controls

Even preventative equipment maintenance should be added to the master record to track lots produced before and after a repair, in the event of a subsequent defect. Capturing the whole picture of your manufacturing and production processes is the only way to ensure the quality and safety of your medical device.

Learn how UFP MedTech can help get your device to market quickly without sacrificing quality. Contact our team today.

References:

1 https://www.fda.gov/medical-devices/classify-your-medical-device/how-determine-if-your-product-medical-device#considerations

2 https://www.qualio.com/blog/medical-device-validation