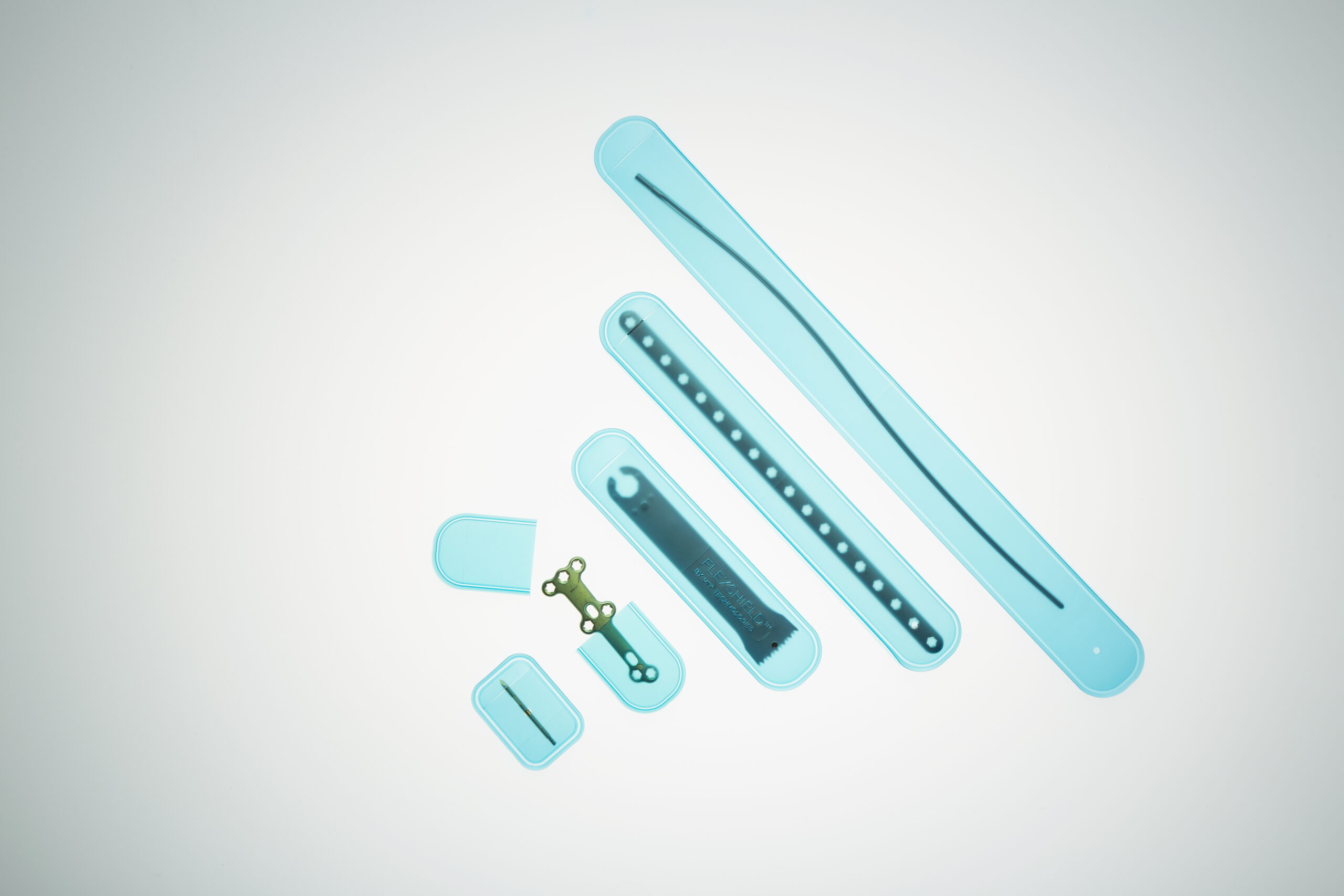

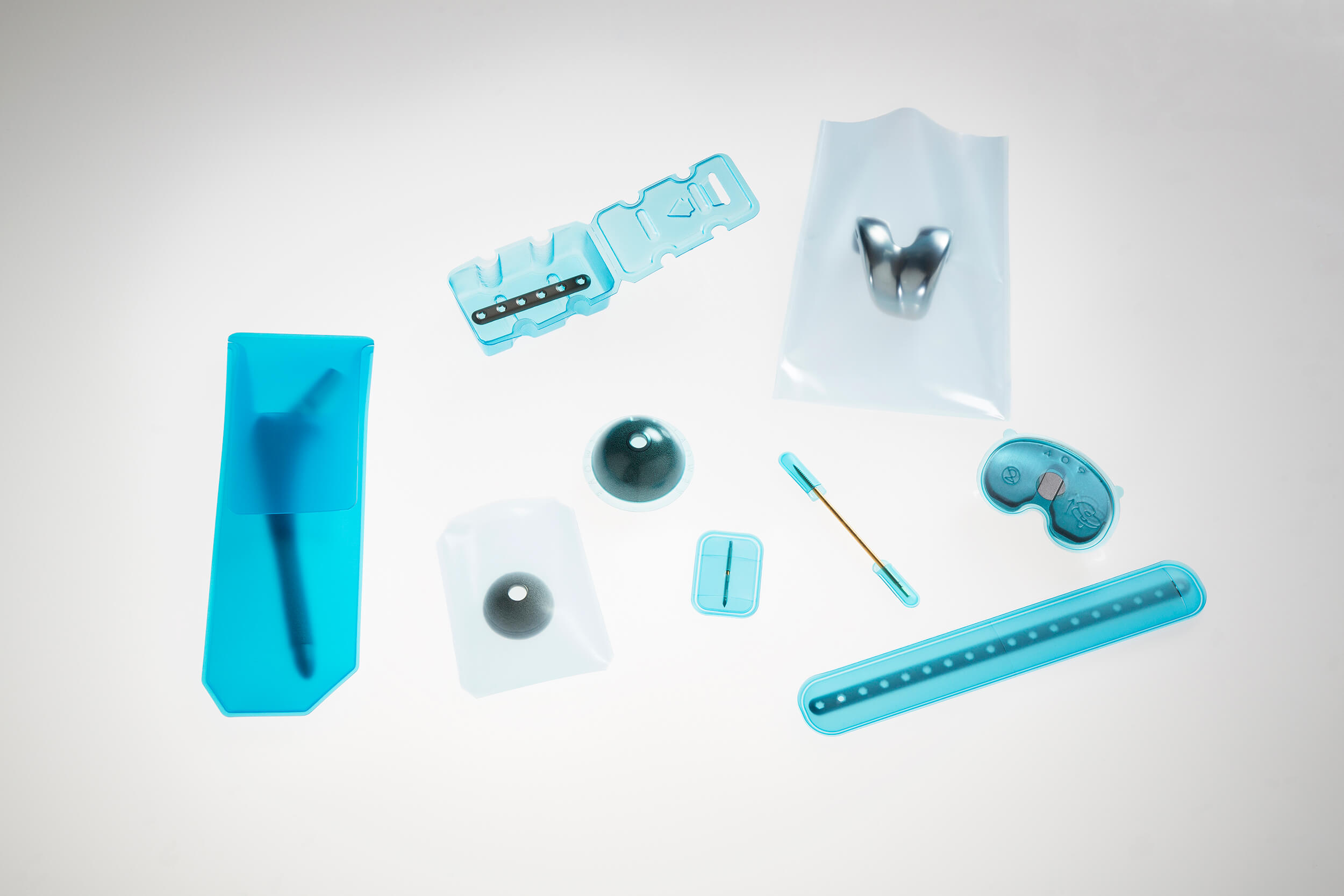

Increase speed to market and eliminate tooling costs with our standard FlexShield packaging solutions. Our standard offerings are designed to accommodate a broad range of products and are available in the following configurations.

FlexShield® TPU Solutions

FlexShield® is a flexible thermoplastic polyurethane (TPU) film used for a variety of solutions including packaging for orthopedic implants and surgical instruments, protection for medical equipment, and other applications that require sterile barrier protection.

FlexShield Sterile Barrier Solutions

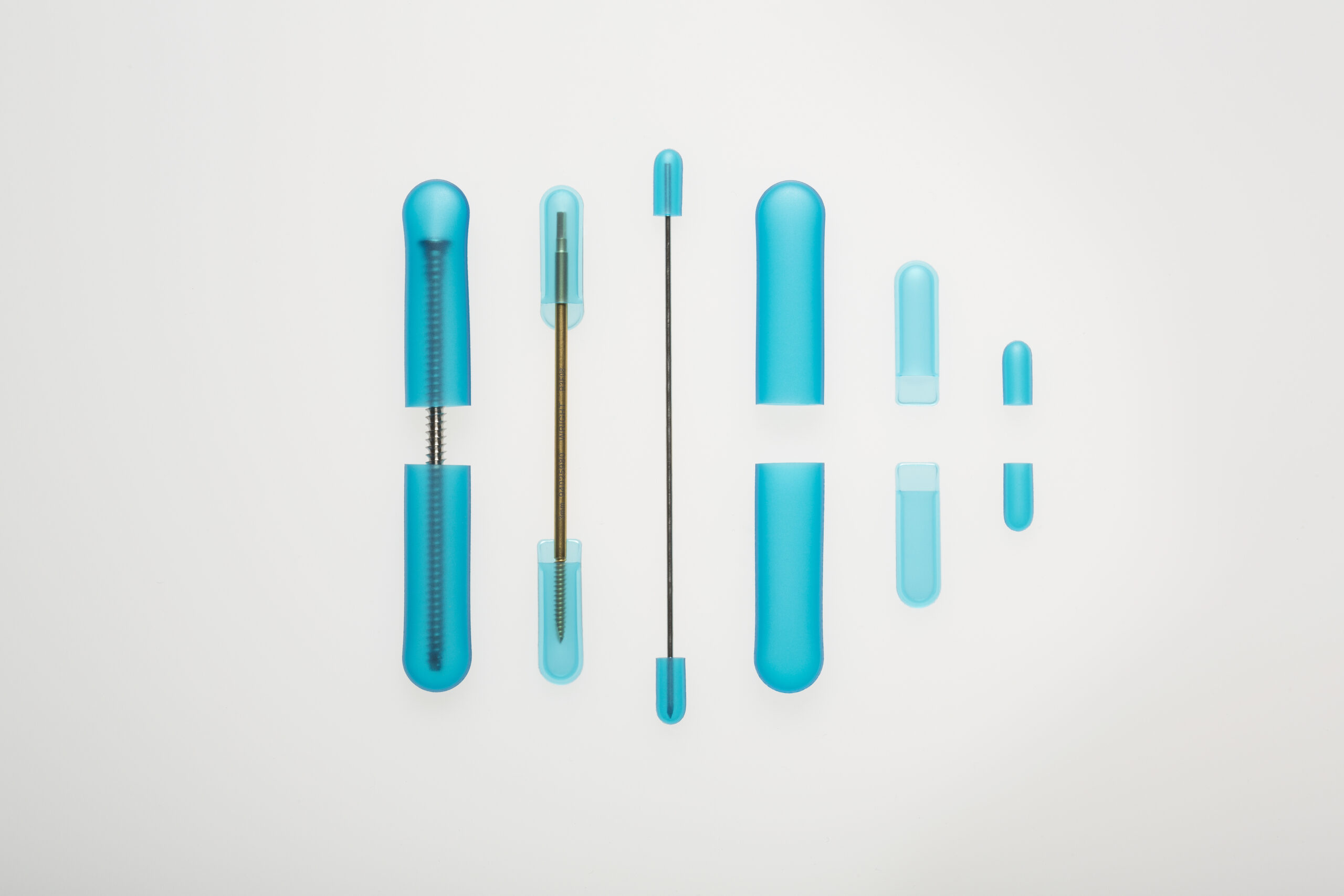

FlexShield offers unmatched puncture and abrasion resistance, ensuring the safe shipment of medical devices, implants, and instruments without damage to its external packaging. We create standard and custom sterile barrier solutions for a wide range of medical products including:

- Orthopedic implants

- Surgical instruments and tools

- Catheters

- Surgical robot drapes, wearables, and more

Features

Puncture & Abrasion Resistant

Biocompatible

Sterilizable

Moldable

Standard Packaging Solutions

Pouches

Designed with surgeons and nurses in mind, pouches break apart to provide effortless aseptic presentation.

Tip Protectors

Used to protect the ends of sharp, delicate medical instruments such as surgical screws, pins, and trocars.

Bags

Provides versatility as a packaging medium and can be used across multiple medical products of varying sizes.

Tubs

Designed to nest inside of a rigid plastic tray and hold a variety of part sizes, which allows for SKU consolidation.

Available Sizes for Standard Packaging Solutions

| FlexShield Product | Available Sizes (In Inches) | Suggested Applications |

|---|---|---|

| Pouches |

|

|

| Tip Protectors |

|

|

| Bags |

|

|

| Tubs |

|

|

For specialized applications, our team will collaborate with you to design and develop custom FlexShield packaging solutions that are tailored to your exact requirements while providing the same unmatched sterile barrier protection as our standard products.

FlexShield can also be formed into unique shapes for a variety of medical device applications. The material is approved for skin contact and has been used to protect patients from infection during surgery and to safeguard sensitive medical equipment.

FlexShield is made from a medical-grade thermoplastic polyurethane film (TPU).

| Specification | Details |

|---|---|

| Certifications | USP Class VI Resin, FDA Approved, Biocompatible |

| Compatible Sterilizations | EtO, Gamma |

| Thicknesses Available | 0.003″ – 0.055″ |

| Colors | Blue, Natural |

| Finish | Matte, Gloss |

Not all options available in all configurations.

For additional material specifications and mechanical property testing data, download the brochure below.

Our Expertise

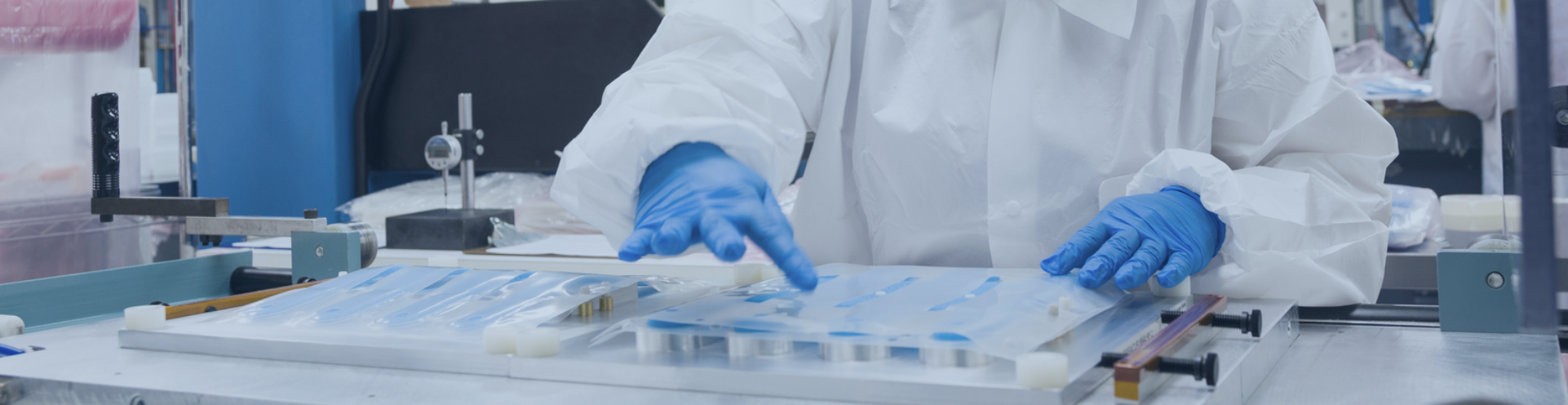

At UFP MedTech, we are uniquely positioned to meet your most stringent demands by offering:

Risk Mitigation

Redundant cleanroom manufacturing capabilities and multiple global suppliers for medical TPU allow us to provide continual, reliable service to our customers.

Speed to Market

A catalog of standard available sizes helps us provide quicker turnaround times and eliminates the need for added design and tooling costs.

Literature

Request a Consultation

Whether you need a partner for one phase of development, or all phases from design through manufacturing, our team of experts can guide you every step of the way.