UFP MedTech’s BioShell® Suspension Pack is at the forefront of technology in the protection of single-use biopharmaceutical bags. The BioShell Suspension Pack is a single-use system that protects biopharmaceutical bags from damage during handling, freezing, storage and transportation. It is a more safe, more durable, and more cost-effective solution in comparison to the traditional keg systems used to transport biopharmaceutical frozen materials.

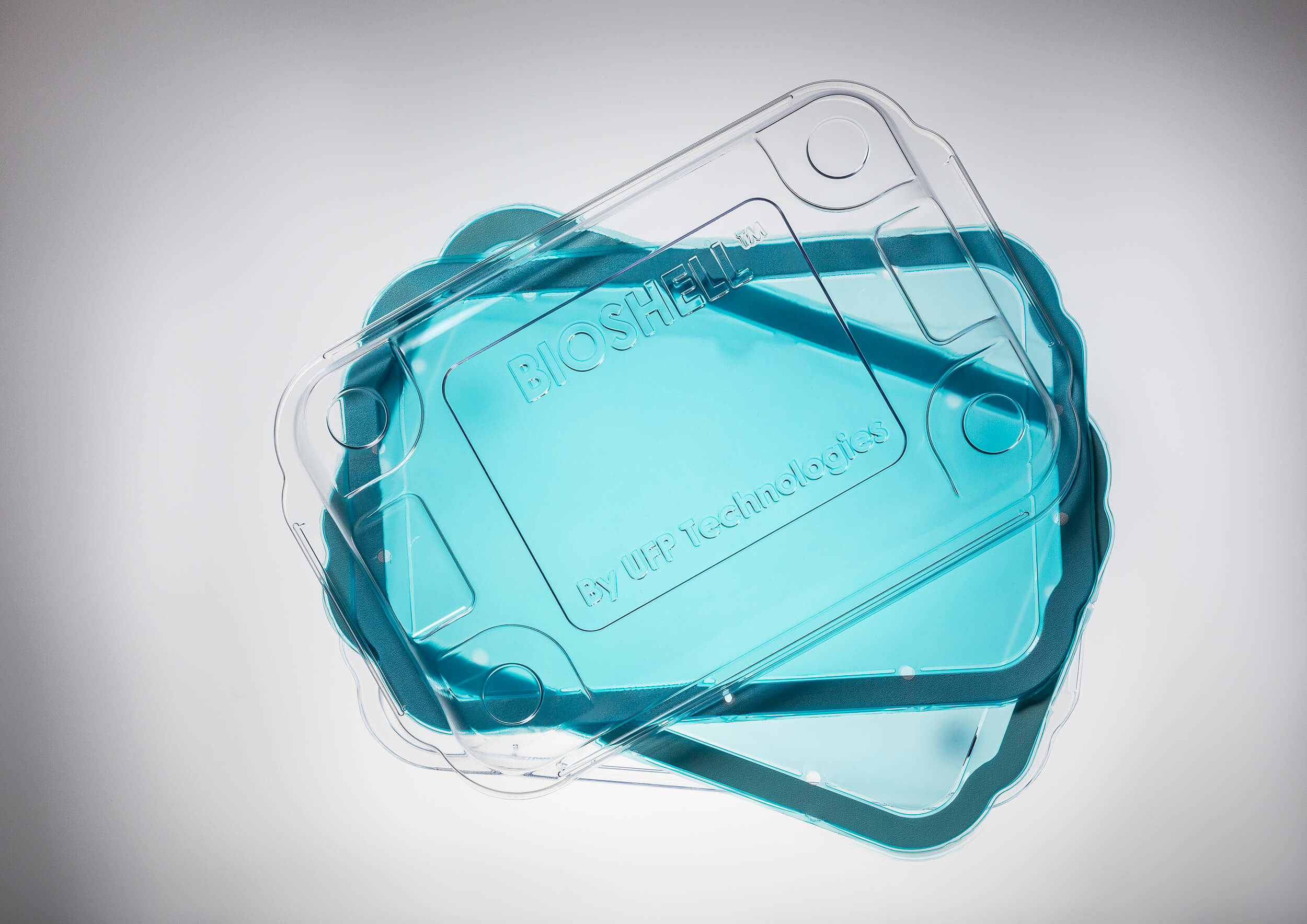

The BioShell Suspension Pack’s unique film molds tightly to biopharmaceutical bags and suspends them within a rigid polycarbonate UV protective shell. The suspension film absorbs shocks during impact, allowing bags to move within a cushion of air, which prevents damage by eliminating contact with the shell. It can absorb turbulence while preventing any sort of chipping, breaking, or ripping of the bags, potentially saving our customers tens of thousands to millions of dollars. Furthermore, its thermally conductive construction allows contents to quickly freeze and thaw. The BioShell Suspension Pack provides the optimal protection, versatility, and fast cycles that bag manufacturers demand all in one, universal storage container.

A number of characteristics make the BioShell Suspension Pack unique compared to other manufacturers of bag protection systems. First and foremost, it offers unparalleled versatility. Unlike its competitors, UFP MedTech has the ability to fully customize the system, or select features, in order to meet the unique requirements of individual customers. Compatible with bags from all manufacturers, the BioShell Suspension Pack can position bags in any orientation and allows for them to be filled to any level. Additionally, it allows for the use of a varying number of tubes, tube lengths, clamps, or filters without sacrificing protection. Its space efficient design provides ample space for data loggers or other accessories.

The BioShell Suspension Pack can also be used for a number of functions, beyond its most traditional purpose. It can serve as a process tray for carts and benches. Moreover, it can also function as a system for liquid bag handling, storage, and transport, simply by removing the suspension system.

Unlike its competitors, the BioShell Suspension Pack offers simplicity in its ability to easily open and close. It does not require any assembly. It additionally provides optimal visibility, with bags, tubes, and accessories all in plain sight. This allows for any possible kinks or stress points to be viewed and correctly quickly.

The BioShell Suspension Pack’s design lends itself the ability to dramatically reduce space, compared to more conventional freezing solutions. This can help save thousands of dollars in storage and transportation costs. It is both stackable and nestable, and is designed to maximize part density in industry standard freezers. As a recyclable and reusable product, the BioShell Suspension Pack can also help to reduce overall life cycle costs. Every component can be fully recyclable, making for an environmentally-friendly solution.

The BioShell Suspension Pack is also unique in its ability to pass severe drop tests compared to its competitors. Below is a video that showcases its superior durability.